Taking inspiration from nature, scientists create a two-component catapult that overcomes limitations in 4D printing.

3D printing, which allows for the easy creation of 3D objects, has recently experienced explosive growth and popularity, with countless applications in many branches of science and technology, from medicine to electronics.

This production method, also known as additive manufacturing, reduces the time it takes to make a part and allows for the manufacturing of different shapes not possible with traditional fabrication methods. However, 3D-printed parts are usually static, while many situations require them to change their properties over time, such as shape or elasticity, in response to varying environments.

4D printing

To solve this problem and enable the introduction of additive manufacturing into complex industries such as automotive, aerospace, and soft robotics, researchers have proposed a solution known as 4D printing. This innovative approach involves programming materials to respond to different external stimuli, such as electric fields, heat, and light, imparting them with dynamic properties.

While the concept of 4D printing holds promise, it still has certain limitations primarily related to the sluggish response of materials used in the 3D printed parts, which impedes their ability to respond quickly to a change in environment.

“4D printing technologies are currently suffering from the inability to produce rapid motions, which limits their applications that require fast shape transformation, such as rapid unlocking and deployment of aerospace equipment,” Qingping Liu, a professor at Jilin University, explained in an email.

To overcome these constraints, Liu and his collaborators from China, the UK and the US came up with an innovative idea. Instead of focusing solely on enhancing the materials used for printed parts to accelerate their shape transformations, they proposed replacing them with objects comprised of two printed components. The first is designed to facilitate the required speed of the part, while the second initiates and sustains motion.

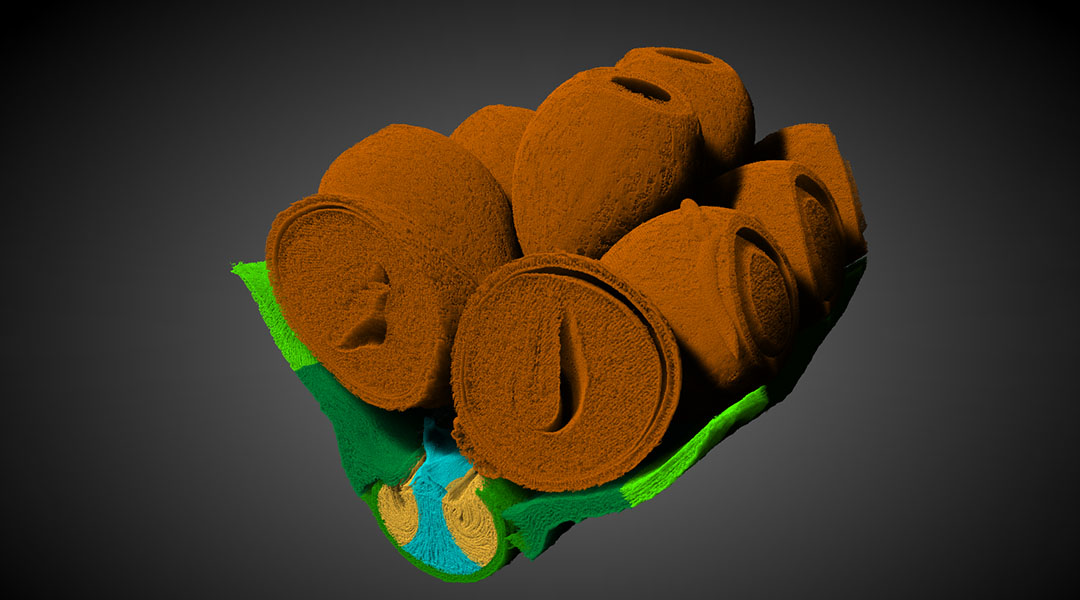

In their study published in Advanced Functional Materials, the scientists say they were inspired by the seed dispersion of a species of violet called Viola verecunda. When the fruits of this flower ripen, the inner surface of the pod containing the seeds loses water, resulting in mechanical stress on the pod’s inner layer.

The strain varies in different regions of the pod, which creates a force that ejects the seeds from the fruit. When shot out of the pod, the seeds reach a speed of several tens of meters per second and an acceleration of about 30,000 times greater than gravity.

A biomimetic catapult

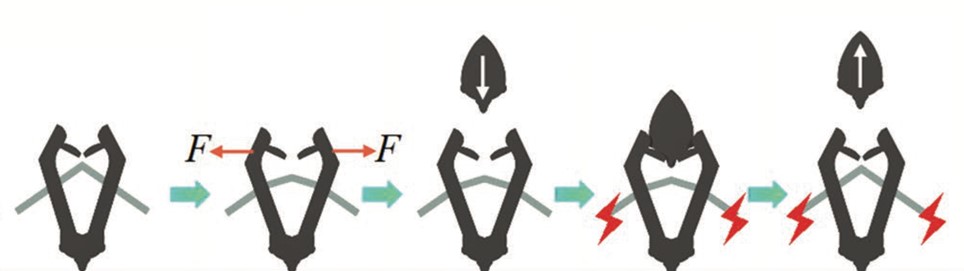

To replicate this mechanism, the team 3D printed a catapult-like object consisting of two parts made of a resin called polycarbonate and a plastic known as polyurethane, each of which react differently to heat. Under increasing temperatures, the two parts contract at different rates, and, like the violet pod, strain is generated within the device, building up force that eventually launches a 3D-printed projectile, pushing a special 3D-printed projectile.

The researchers were unable to achieve the velocity of violet seeds shot out of their pods, but nevertheless, the speed of the projectile was very high according to the standards of 4D printing, reaching several meters per second.

“Just as a Viola verecunda disperses its seeds one by one, the biomimetic catapult was developed via the multi-materials 4D printing technology,” said Liu, summing up the results of the study. “This catapult can achieve high-speed ejection with the stimuli of temperature, light, or electricity. The proposed biomimetic 4D printing strategy has broken through the limitations in motion speed, which helps fully unleash the potential of 4D printing.”

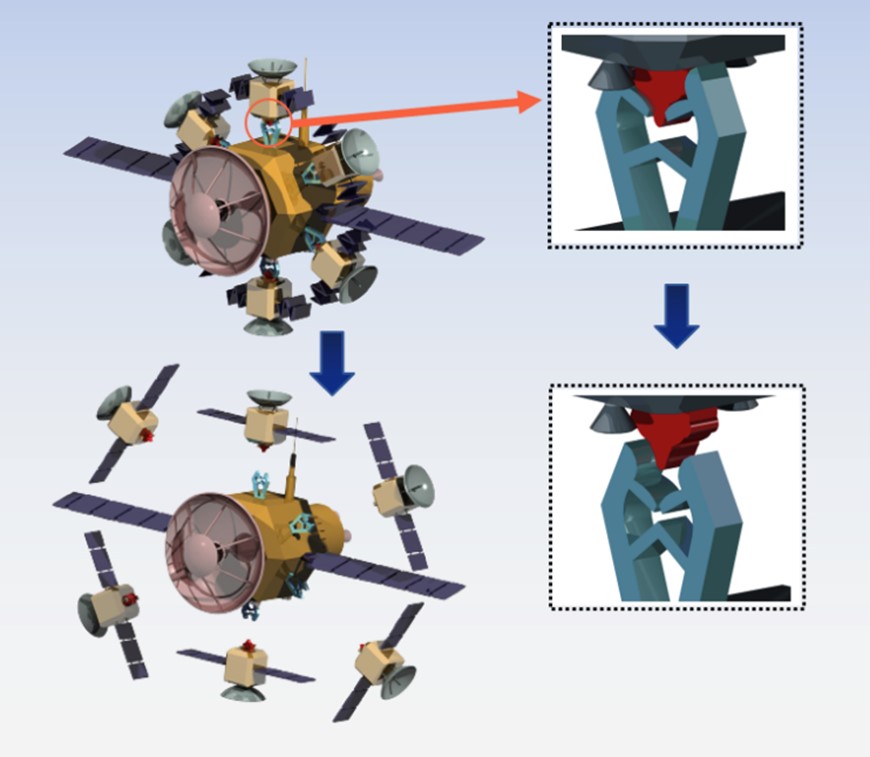

One of the most interesting applications of this 4D-printed catapult is to launch multiple satellites simultaneously. To test if this would work, the team printed tiny models of the satellites and placed them in replicas of the catapult. The satellites successfully launched at intervals of a few seconds without interfering with each other (see diagram), confirming the success of this preliminary test.

However, the team notes that their research is in its infancy, and further investigations are needed before large-scale testing or commercialization. The scientists are exploring the possibility of using other materials popular in 3D printing, such as polymers and metals, in their device.

They hope that this will unleash the full potential of the technology they have developed, significantly expanding the scope of its application.

Reference: Guiwei Li et al., Biomimetic 4D Printing Catapult: From Biological Prototype to Practical Implementation, Advanced Functional Materials (2023), DOI: 10.1002/adfm.202301286

+ There are no comments

Add yours